For custom silicone products, tooling is a necessity. This is because custom products are made to specific specifications and designs that cannot be produced using standard tooling and machinery. Custom tooling and machinery is typically designed and built specifically for the production of a particular product and is often unique to that product. The process of creating custom tooling and machinery for a custom product is known as custom tooling and is an important step in the production of many custom products. Tooling represents a significant investment in the overall cost of developing a custom silicone product.

1.What is the cost of tooling?Tooling costs are the costs associated with producing the tools and machinery used in the manufacturing process. This can include the cost of designing and manufacturing the tools, as well as the cost of maintaining and replacing them over time. Tooling cost is an important factor to consider in the manufacturing industry as it can have a significant impact on the overall cost of producing a product. In general, the more complex and specialised the tools and machinery required for a manufacturing process, the higher the tooling costs.

2.Why is tooling important?

Tooling costs are important for a number of reasons.

Firstly, it is a significant expense for manufacturers and must be carefully managed in order to control overall production costs.

Secondly, the tools and machinery used in manufacturing processes play a critical role in the quality and consistency of the products produced. Therefore, investing in high quality tooling and machinery can help ensure that products meet the required specifications and standards.

Finally, the cost of tooling is also important as it can affect the speed and efficiency of the manufacturing process. High quality tooling and machinery can help to increase production speed and reduce downtime, which can help to improve overall productivity.

3. Is tooling a fixed cost?

The cost of tooling varies from project to project because it depends on so many variables. It should therefore be allocated directly to the product. How much you pay for new tooling depends largely on the project, but manufacturing overseas will significantly reduce your tooling costs compared to domestic manufacturing.

4. What are the cost drivers for tooling/mould cost?

There are 7 factors that can drive up the cost of tooling, including the complexity and quantity of tooling and machinery required, the materials used and the level of precision and accuracy required.

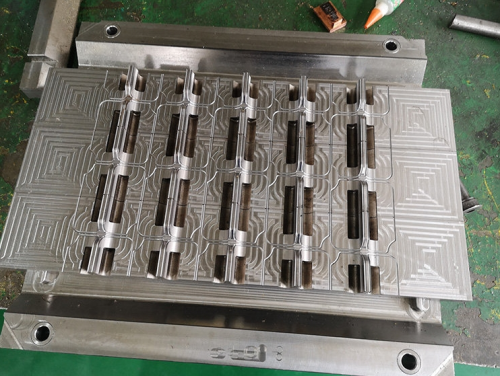

1) The complexity and precision of the tooling and machinery required: More complex and specialised tools and machinery typically require more time, skill and resources to produce, which can increase costs.

2) The materials used: The cost of tooling can also be influenced by the materials used to make the tools and machinery. For example, the use of high quality materials such as carbon steel or tungsten carbide can increase costs, but can also improve the durability and performance of the tools.

3) The lead time of the tools and machinery required: The cost of tooling can also be influenced by the machining time required for CNC machining. In general, the longer the CNC machining time, the higher the tool/mold cost.

4) The level of precision and accuracy required: The level of precision and accuracy required for the tooling and machinery can also affect the cost. For example, tools and machinery that require high precision and accuracy, such as those used in the aerospace or medical industries, may require more complex and specialised manufacturing processes, which can increase costs.

5) The type of manufacturing process used: The cost of tooling can also be influenced by the manufacturing process used to produce the tooling and machinery. For example, a mould that requires an EDM process will cost more. Electrical Discharge Machining (EDM) is a manufacturing process that uses electrical discharges to remove material from a workpiece. This process can be used to produce very precise and complex shapes and is often used for hard or difficult-to-machine materials such as tungsten carbide, tool steel and other high-strength alloys. EDM is generally considered to be more expensive than CNC machining, which uses cutting tools to remove material from a workpiece. CNC machining is a more common and versatile manufacturing process and is generally less expensive than EDM.

6) The size of the tool/mold also affects the cost: the mould with more cavities will be larger, requiring more mould material and longer machining time, thus increasing the cost.

7) Surface treatment, such as plating or coating, can affect the cost of tooling: for example, if the tools and machinery used in the manufacturing process require a specific type of coating or plating, this can increase the cost of the tooling.

Ray Xian

Phone/Whatsapp: +8619902910431

Email/Skype: [email protected]

Copyright © © Copyright 2024 Shenzhen WQ Silicone Rubber Products CO,. LTD All Rights Reserved - Privacy policy